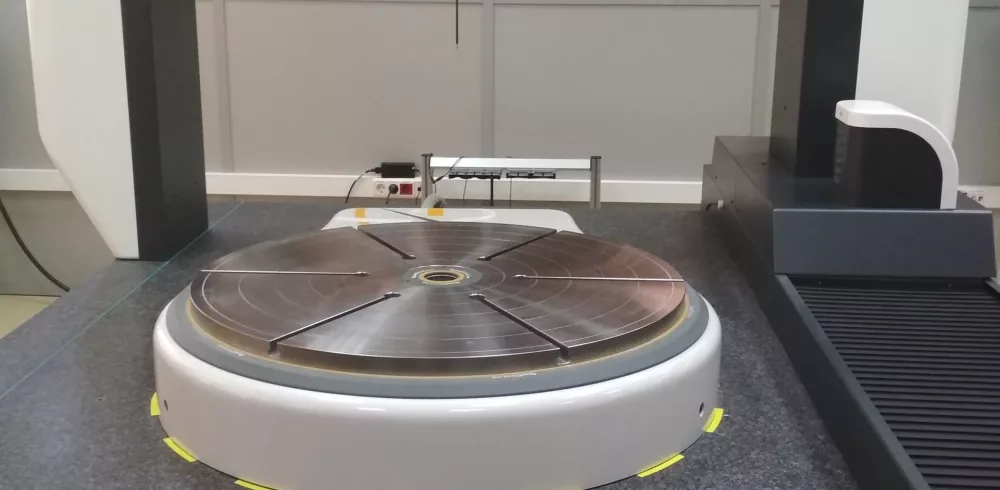

Wenzel’s Bulgarian distributor has been supplied with a QuadSlimLine rotary table by RPI UK, the world’s leading specialist developer and manufacturer of precision positioning devices for high accuracy rotary and angular inspection systems. This will be integrated into a Wenzel CMM machine to enable a European aerospace giant to measure blisk blades, saving up to 40% in inspection time.

As an ideal addition to high precision CMM machines, RPI’s rotary tables have been specifically designed as a fourth axis with an accuracy of +/- 0.5 arcs seconds. This is equivalent to hitting a golf ball at a hole more than 22 km away and scoring a hole in one every time!

Rotary tables can significantly improve overall measurement accuracy and reduce uncertainty in a CMM machine, as well as increase a CMM machine’s available measuring volume, thereby providing greater flexibility in what can be measured.

The installation of the QuadSlimLine onto the Wenzel CMM was carried out by 2M Trading, Bulgarian distributors for both RPI and Wenzel.

“We installed RPI’s Quad Slimline on to Wenzel’s CMM LH108 NG incorporating a Renishaw UCC S5 controller and Renishaw MODUS software. The result was a CMM which worked smarter with increased flexibility, capacity and throughput which resulted in a 40% reduction in inspection time for one of Europe’s major aerospace manufacturers! They’re so impressed they’ve ordered another two QuadSlimLines to be installed onto their CMM machines later this year,” said Timothy Matyushin, 2M’s General Manager.

Bath-based RPI has a very large share of the market in those CMMs which use rotary tables and can boast more than 728 successful installations worldwide.

The QuadSlimLine is part of RPI’s Quadrant range of CMM tables which also includes the Quad Dual Purpose and the Quad Airmatic. They come in a wide size range; from Ø200mm to Ø1500mm and can be fully integrated to the host machine controller.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News